Functional component

Functional component

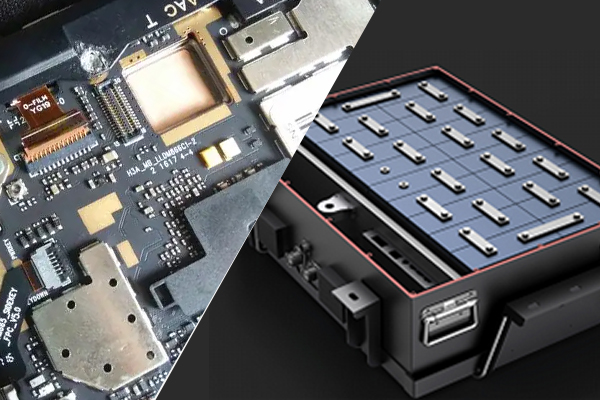

The company's precision functional components and structural components have achieved precise composite of multiple materials, integrating various functions such as heat dissipation, connection, protection, anti-interference, dust prevention, insulation, marking, shading, shock absorption, buffering, sealing, conductivity, support, shielding, and fastening. The company's precision functional components are delivered by the customers to well-known manufacturing service providers or component manufacturers such as Foxconn, Jingyuan Computer, BYD, Quanta Group, Xianglong Electronics and Luxun Precision. These products are ultimately applied to the smartphones, laptops and all-in-one computers, tablets, smart home appliances, AI glasses, vertical take-off and landing aircraft and other products of the aforementioned well-known terminal brand manufacturers. 。 |

Metal parts

Metal parts

The precision functional structural components of metals are manufactured from various metal materials, copper foil, adhesive materials, foam and other flexible materials. They can simultaneously perform multiple functions such as support, shock absorption, waterproofing and concealment. Multifunctional metal dust-proof screen for speakers: Application areas: Tablet computer speakers, smart TV stick mainboards, etc. Purpose: Horn-shaped design provides waterproof and dustproof protection, sound effect filtering, overall sealing, shock absorption, and high-quality appearance components, etc. Local shielding within the product, thermal management, support, bonding, etc. |

Traditional precision components

Traditional precision components

The company's traditional precision components are all customized according to customer requirements. There is strict control over product size tolerances, product weight, and the desired process effects. Coverage: Double-sided adhesive for the front cover glass frame Front/rear camera hot glue FPC adhesive double-sided tape Mainboard conductive adhesive Back cover with all-round conductive foam material Touchscreen sealed foam pad High-temperature insulating tape Shielding insulating self-adhesive tape |

Metal etching parts

Metal etching parts

(2) Continuous etching roll by roll Continuous roll-to-roll etching is also known as RTR continuous etching. It means that the entire production process from raw materials to finished products is carried out using roll-type material tapes. The process flow is "RTR cleaning - RTR applying photosensitive film - RTR exposure - RTR developing - RTR etching - inspection - packaging". It is quite different from sheet-based etching. The automation level throughout the production process is very high. Continuous roll-to-roll etching is mainly used for products with high precision and high requirements for post-processing automation, and it is usually applied to products with a material thickness of less than 0.3mm. | The company's etching products can precisely fabricate channel arrays on ultra-thin metal substrates, achieving complex three-dimensional microstructures and gradient aperture designs. Compared with traditional mechanical processing, they can significantly improve heat dissipation efficiency and possess excellent heat dissipation performance. (1) Conventional film-based etching Traditional metal etching involves using sheet-like metal materials of specific specifications, and through a series of processes such as "washing - coating - exposure - development - etching - inspection - packaging", the raw materials are processed into the final product. The entire process is completed with the assistance of manual operations. Sheet etching is a flexible etching processing method, suitable for small-batch or mass production of products of various specifications, sizes and thicknesses. |

Fastener

Fastener

Fasteners are a type of mechanical parts used for connecting and fixing two or more components. They are widely used in various mechanical, equipment, vehicles, ships, construction and other structures. The processing dimensions of the company's screw products range from M0.6 to M24. They have obtained patent authorization from companies such as German EJOT, American ACUMENT, Japanese OSG, and Lianshang Precision Technology (China) Co., Ltd. The products are widely used in fields such as mobile phones, computers, household appliances, electric vehicles, and new energy vehicles. |